Head of Additive Manufacturing / Intake Manifold Lead

Overview

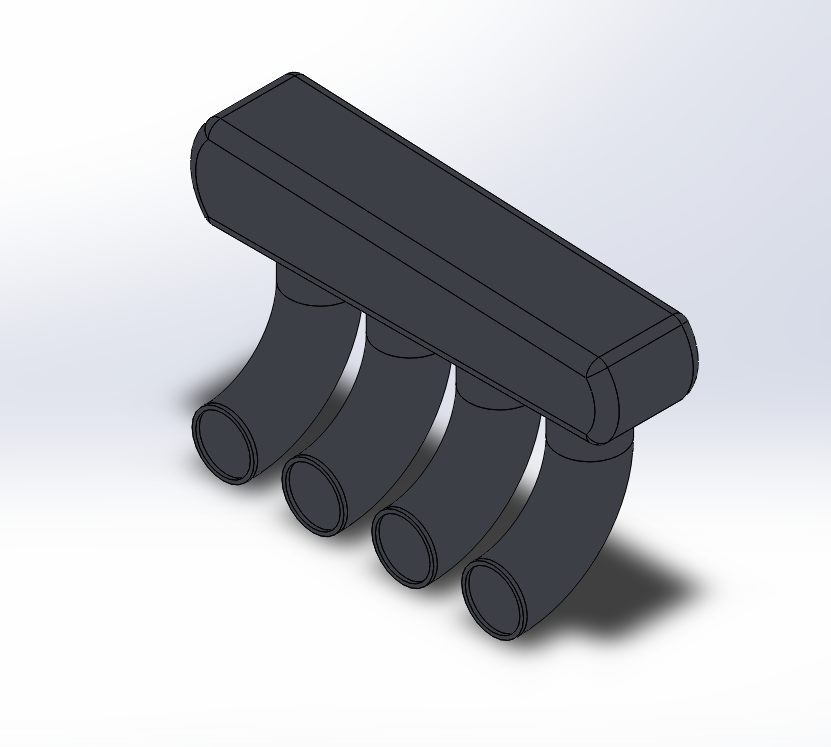

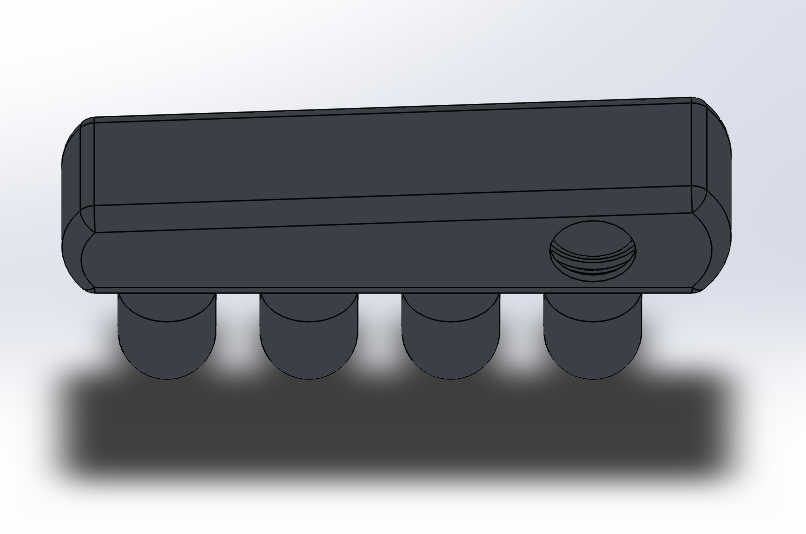

Work-in-progress custom intake manifold design focused on high-performing runner/plenum geometry and a cheap, manufacturable design

Emphasis on smooth flow transitions, high volumetric efficiency (VE), and optimized velocity stack design

Documenting design revisions and decision-making as the model evolves

My Role

Led the intake manifold concept and owned the CAD model through multiple design iterations

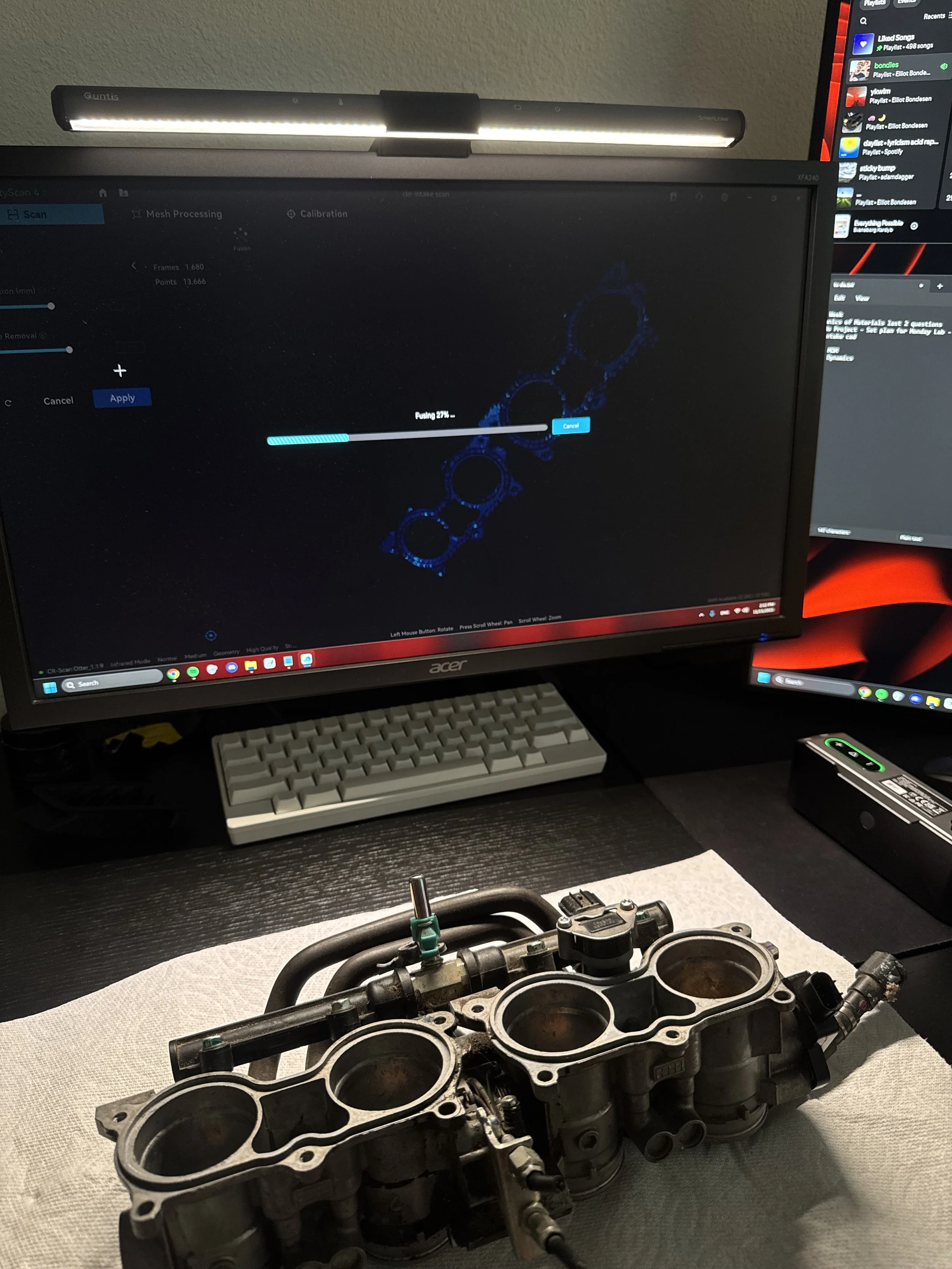

3D-scanned the OEM throttle body and used the scan data to accurately model a flange

Supported prototyping/fitment/testing through 3D-printing and fed results back into design updates

Provided research, guidance, and technical direction for the team, helping understand requirements, avoid common mistakes, and keep the project moving

Challenges

Managing tradeoffs between runner shape/length targets and overall manifold size/complexity

Creating clean internal transitions without sacrificing manufacturability

Keeping airflow to a maximum, even with a restrictor plate

Working within tight clearance constraints near the firewall while maintaining serviceability